Main/Portfolio/How We Developed an AgroTech Information System for iFarm

iFarmHow We Developed an AgroTech Information System for iFarm

How did we develop an information system that replaces rare, expensive work resources, improves operations management, and helps solve strategic issues? Keep reading to learn about our solution for the AgroTech startup, iFarm.

Have you ever wondered how food gets to your table? How many kilometers do products travel before getting to your plate? How much food goes bad before it appears on the shelves in stores? What is the carbon footprint of each fruit, vegetable or berry? According to experts, half of the world’s fertile land has disappeared in the past 150 years, and the rest will be lost in the next 60. The cities are growing in population rapidly, and people need new, effective ways to produce food.

These issues led the founders of the startup to create a solution that helps farmers grow environmentally friendly, tasty and healthy products anywhere in the world, all year round while saving space too. iFarm offers business and private customers worldwide city farming technologies based on the farm-to-table concept: natural products get on the plate with a minimum of stops on the way from the farm. The key to this solution lies in using automated, local vertical farms and year-round greenhouses.

Today, in Russia, 2,000 m² of vertical farms are using iFarm technology, 9,000+ m² are at the construction and design stage, including countries such as Finland, Latvia and Lithuania. iFarm products are already being delivered to supermarkets and companies in the HoReCa segment.

The Scope

Growing organic, ultrafresh products on an industrial scale year-round requires extensive technical and financial resources. In addition to the expensive infrastructure, highly paid qualified specialists – agronomists of closed soil – are required. The demand for such specialists is increasing and the number of human resources of this specialty is in decline. To solve this issue, iFarm asked Azoft to develop a system that automates the routine work of agronomists, plant growers, sales managers and logisticians. With the help of this system, iFarm clients will be able to reduce the cost of each kilogram of vegetables, herbs and berries and deliver high-quality crops on time. It also allows for managers and stakeholders to effectively manage the business and determine directions for further development.

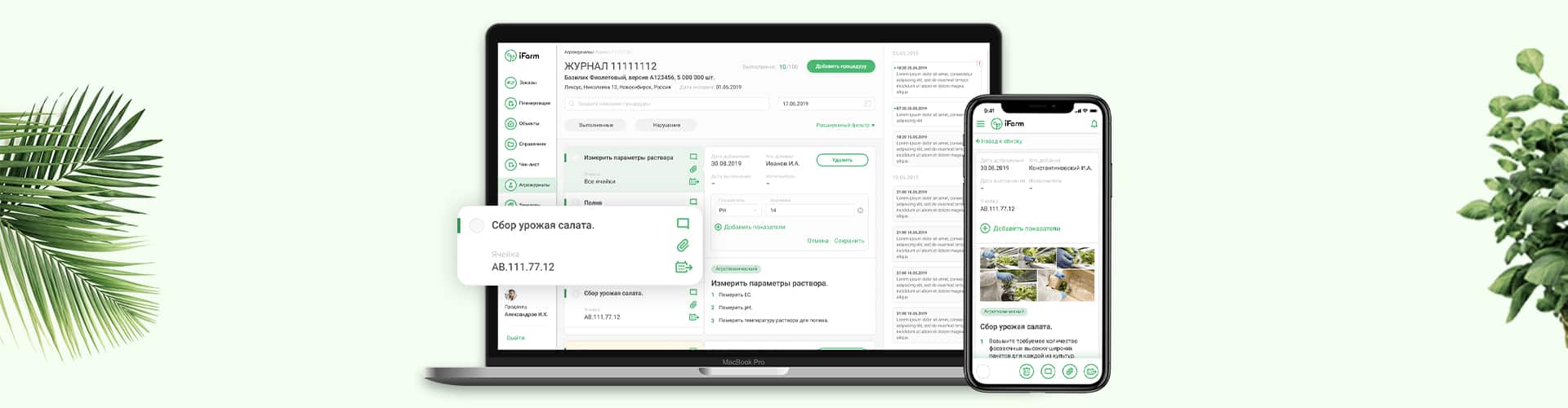

Azoft was tasked with developing a holistic IT infrastructure consisting of web (desktop, tablet, mobile) and server components.

The Solution

In the spring of 2019, with great enthusiasm, we started the project. To meet the expectations of the stakeholders we began with analytics. Delving into the details of the project, we realized that the system would be large and consist of several modules. The number of stakeholders was increasing. Each of them had his own view of the system and how it should operate. Then, the client made a wise decision and added a qualified product technologist in the project to systematize requirements and eliminate contradictions.

It was important for the customer to start planning the production cycle. Therefore, for the first stage of development, the following functional blocks were allocated: Planner, Checklists, Agricultural Journals, and Dashboard.

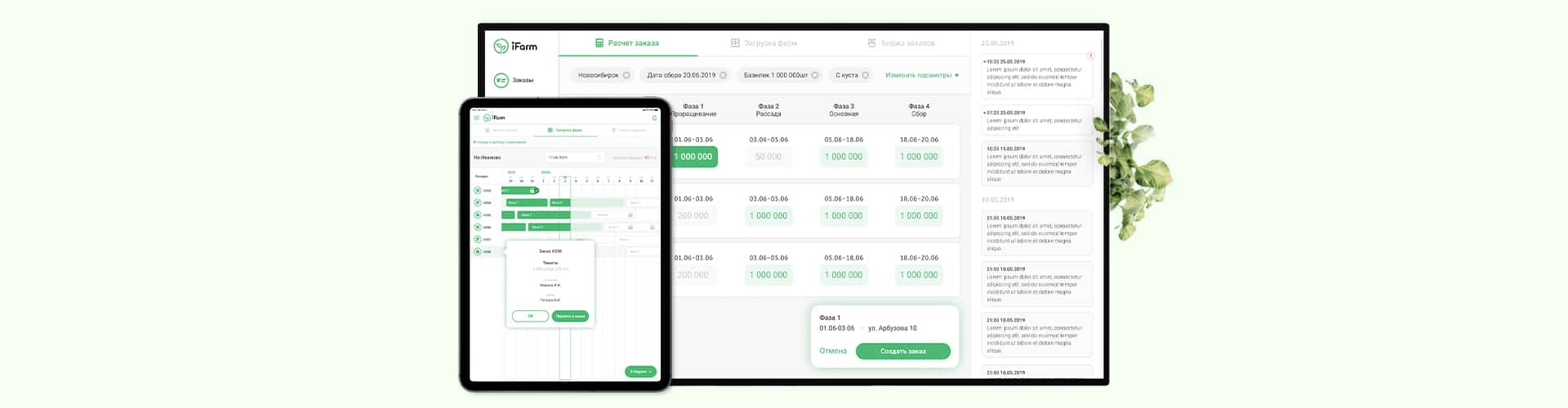

Planting and Farm Capacity Planner

This is how it works. Imagine that “Whole Foods” ordered 1,000 salads by April 15th. Using the system, a sales manager would enter the initial parameters of the order: cropper, variety, version (actual or experimental), date and amount. The system would then check the available space on all connected farms that meet the conditions of the order. Then, it would automatically offer options for placing an order. The planning algorithm would take into account future production capacities and compatibility with crops currently growing on the farm.

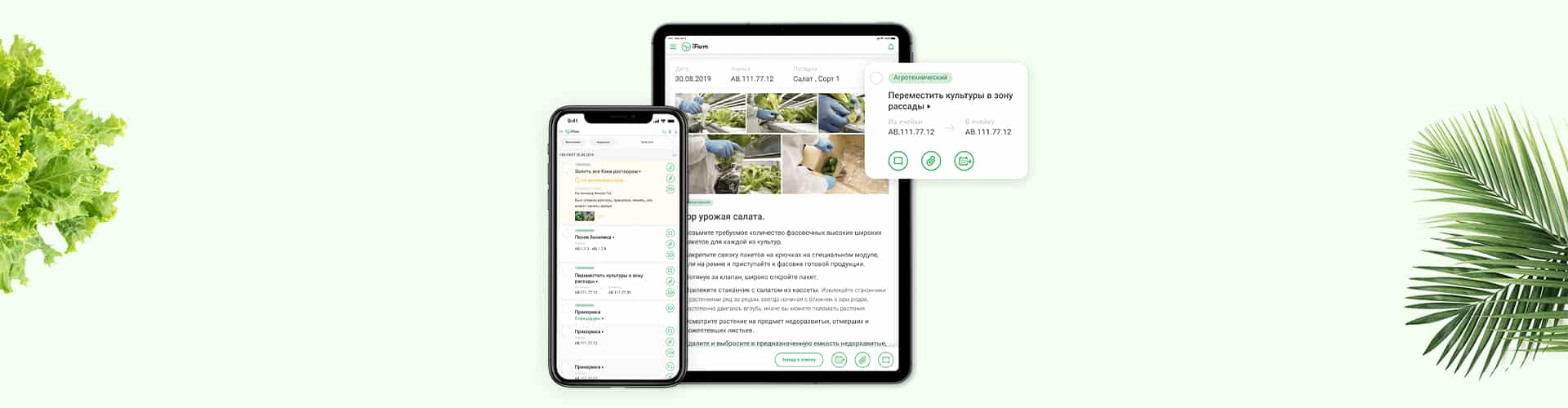

Checklists

After an order confirmation, the system automatically creates a checklist – a list of tasks for farm staff responsible for planting. On the appointed day, crop growers receive lists of tasks that need to be completed in a specific order. These lists are step-by-step instructions for everything from planting seeds to collecting and packaging final products. At the end of the day, the staff responsible for production view the status of tasks. They get notifications if there are any unresolved tasks.

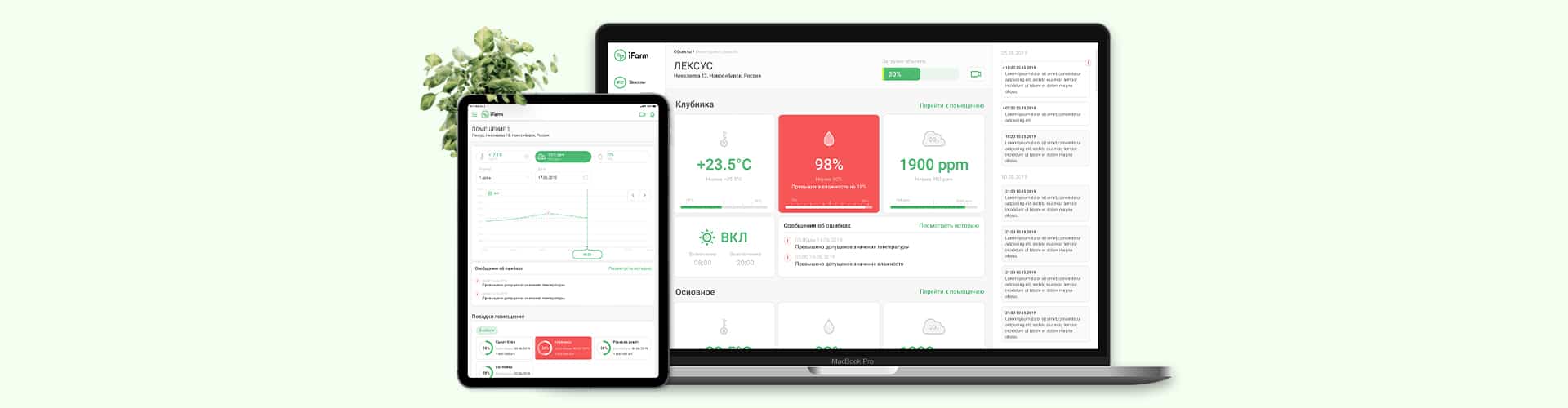

Dashboard

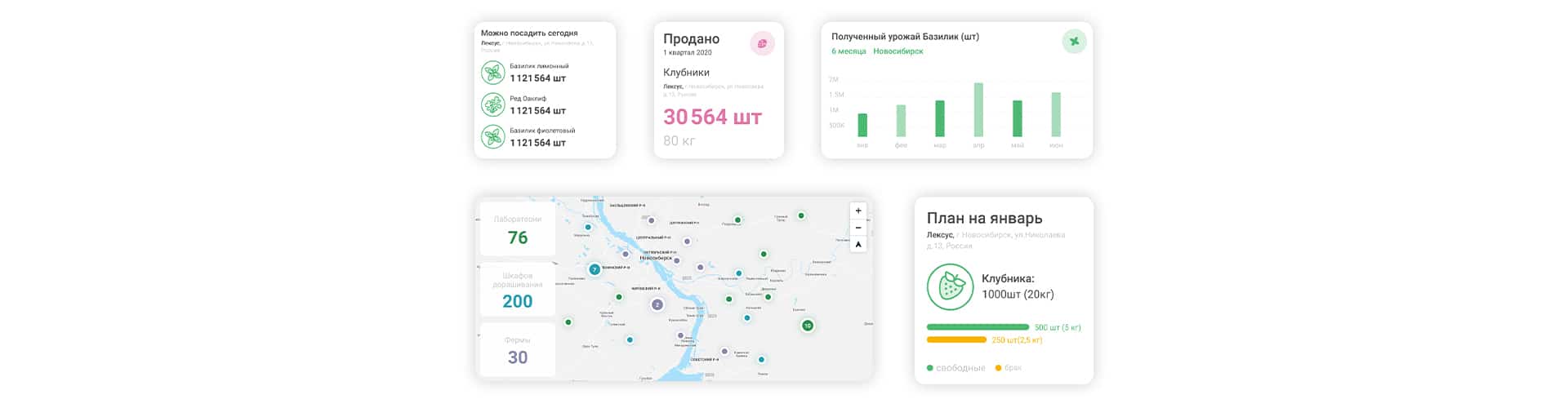

With this module, the clients of iFarm and farmworkers monitor important performance indicators including, but not limited to, humidity, lighting, air temperature, pH and CO2. They also track the dynamics of indicators and deviations from predetermined target indicators. When the system detects an incomplete task, a critical change in indicators or a new order confirmation, it sends a notification to the responsible personnel.

Farm climate IoT sensors integrated into iFarm technologies transmit real-time data to servers where they are stored for processing by a neural network. Key indicators for each user are displayed as user-friendly summary analytics.

Within the dashboard, we developed a monitoring module that visualizes statistical sections. Using the monitoring module, users will be able to track the number of varieties, crops, versions, planned and actual production volumes and sales, and indicators of production capacity. This data will be used to make operational management decisions. Information is displayed using widgets that can be flexibly customized. For instance, users can select certain parameters to be shown, change the sizes of the widgets, rearrange them and configure their contents.

Agricultural journals

This module helps agronomists keep a diary of experiments with cultivation. It allows users to record the events of experiments, systematize knowledge about the tests performed and structure and create new versions of technological maps. To improve the quality of crops grown, iFarm customers will be able to download improved versions from the technical map like the App Store or Google Play.

Autopilot drones

In addition to the information system, we are developing an autopilot drone that captures the planting process on vertical farms. To do this, we use machine learning and computer vision technologies. The drone will regularly fly around the shelves, take pictures of plants and send them to the server for further analysis and processing. Our current task is to test and debug hardware and computer vision algorithms.

The outcome

Together with iFarm, we developed a system that helps to manage production effectively, monitor processes in real time and make decisions on further business development. Due to the maximum automation of processes, the system reduces the cost of rare resources and the cost of ownership of equipment.

By now we have completed two stages of development. Thanks to well-coordinated cooperation with the client, we created a solution that:

- offers best planting options that assure full utilization of farms;

- provides plant growers with clear instructions on how to care for plants;

- controls daily agricultural work;

- allows users to monitor climate and production on farms online;

- predicts when the order will be ready;

- reduces the workload of farm personnel.

iFarm is satisfied with the results Azoft delivered. Now, we are moving on to the next stage. We plan to further develop the system by:

- receiving and analyzing feedback from users of the system and drawing conclusions on further improvement of the system;

- integrating with the warehouse accounting system so that the Planting Planner will take into account the available inventory;

- improving the internal messaging system and integrating the ticket system.

There are a few more parts of this case ahead. We will tell you more about the new functions of the system and the results of working with drones. See you soon!

Stack

Node.js, Yii2, Angular

Related projects

-

Azoft WebChat

Learn more